Powder coating has emerged as a flexible and high-performance solution. It involves applying a fine powder composed of pigment, resin, and additives onto a surface, typically through an electrostatic spray gun. Powder coating offers several advantages over traditional liquid paint finishes. It produces a thicker and more consistent coating, with minimal dropping or running.

Understanding of Powder Coating

Powder coating is a dry finishing process that involves applying a finely ground mixture of pigment, resin, and additives onto a substrate. The powder coating formulation typically consists of three main components:

Pigment:

Pigments provide color and visual appeal to the powder coating. They come in a wide range of colors and can be customized to match specific requirements or design preferences.

Resin:

Resins serve as the binder that holds the powder coating together and forms a protective film upon curing. Common types of resins used in powder coating formulations include epoxy, polyester, polyurethane, and acrylics.

Additives:

Additives are included in the powder coating formulation to enhance specific properties such as flow, adhesion, UV resistance, and texture. Examples of additives include leveling agents, flow modifiers, and UV stabilizers.

How Powder Coating Is Made

Before applying the powder coating, proper preparation of the substrate is essential. This involves cleaning the surface to remove any dirt, oil, or contaminants that could affect adhesion. Depending on the material, additional steps such as sandblasting or chemical etching may be necessary to ensure optimal surface adhesion.

Manufacture Of Powder Coating

The manufacture of powder coating involves several key steps to produce the fine powder used in the coating process. Here’s a Complete Guide to powder coating:

Raw Material Selection:

The first step in powder coating manufacturing is selecting high-quality raw materials. These typically include resins, pigments, additives, and curing agents. Resins provide the film-forming properties, while pigments impart color and additives enhance specific properties such as durability or texture.

Mixing and Pre-Blending:

Once the raw materials are selected, they are mixed and pre-blended to achieve a homogeneous mixture. This ensures a uniform distribution of components throughout the powder coating formulation.

Extrusion or Melt Mixing:

The pre-blended powder coating formulation is then processed through an extruder or melt mixer. This equipment heats the mixture to melt the resin and blend it thoroughly with the other ingredients. The resulting molten mixture is then cooled and solidified into a solid mass.

Grinding and Milling:

The solidified mass is broken down into smaller particles through grinding and milling processes. This step is crucial for achieving the desired particle size distribution and consistency in the powder coating formulation.

Filtering and sorting

The ground powder is sieved and classified to remove any oversized particles and ensure uniformity in particle size. This helps maintain consistency in the application and performance of the powder coating.

Additive Incorporation:

Additional additives, such as flow agents, leveling agents, or texture modifiers, may be incorporated into the powder coating formulation at this stage to enhance specific properties or achieve desired effects.

Cooling and Packaging:

Once the powder coating formulation is finalized, it is cooled and packaged for distribution. The packaged powder coating is typically stored in a controlled environment to maintain its quality and stability until it is ready for use.

Throughout the manufacturing process, quality control measures are implemented to ensure that the powder coating meets the required specifications and performance standards. This includes testing for factors such as particle size distribution, color consistency, adhesion, and durability. By adhering to strict quality control protocols, manufacturers can produce high-quality powder coatings that deliver reliable performance in various applications.

How To Powder Coat At Home

Powder coating at home can be a good rewarding DIY project and it requires careful preparation, the right equipment, and safety measures. A step-by-step guide to powder coating at home includes.

Prepare Your Workspace:

Choose a well-open-air area with enough space to accommodate your project and equipment. Make sure that the space is free from dust and flammable materials. Cover any surfaces you want to protect from overspray.

Prepare the Object for Coating:

Clean the object carefully to remove any dirt, grease, or residues. You can use a cleaner and water or solvent-based cleaner for this purpose. Make sure that the object is completely dry before proceeding.

Preheat the Object (Optional):

Heating up the object can help the powder adhere better and reduce the risk of errors. If you choose to preheat, place the object in an oven set to the required temperature for the specific powder you’re using.

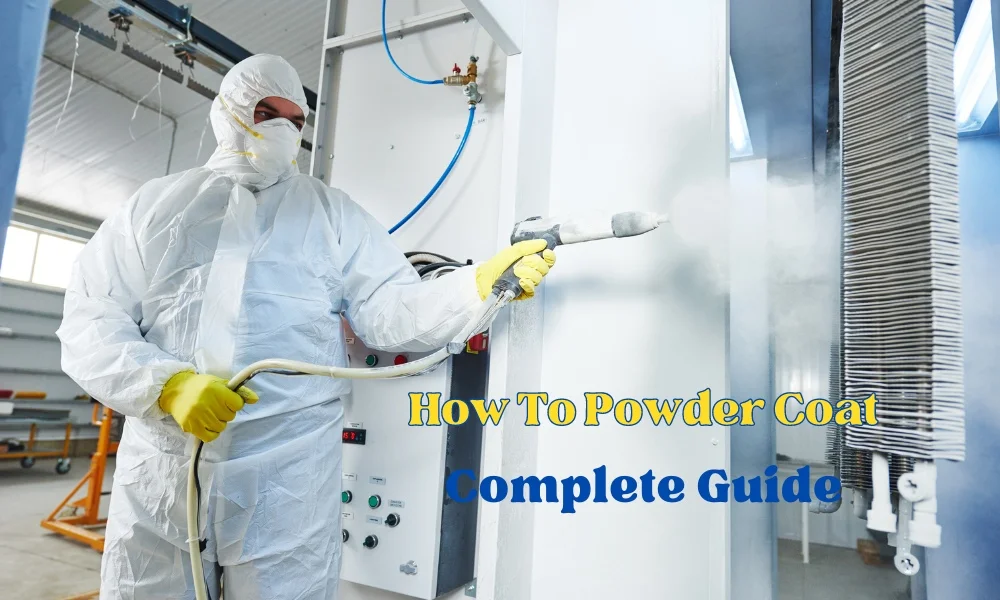

Apply the Powder:

Using an electrostatic powder coating gun, apply the powder smoothly to the surface of the object. The gun gives the powder a positive charge, which attracts it to the grounded object. Be sure to cover all areas uniformly, but avoid applying too thick a coat to prevent runs or drops.

Cure the Powder:

Once the object is coated, transfer it to an oven for drying. Follow the manufacturer’s instructions for the required drying time and temperature. Typically, drying temperatures range from (150°C to 230°C), and hardening times can vary from 10 to 30 minutes depending on the powder.

Cool and Inspect:

After drying, allow the object to cool completely before handling. Once it is cooled, inspect the coating for any errors or imperfections. If necessary, you can recoat and dry the object to achieve the desired finish.

Cleanup:

Clean up your workspace and equipment carefully after completing the powder coating process. Dispose of any unused powder according to local regulations.

Safety Precautions:

Wear suitable personal protective equipment, including gloves, goggles, and a mask, to protect yourself from vulnerability to powder and fumes. Work in open-air areas to minimize inhalation of airborne particles and fumes.

Practice:

Powder coating takes practice to master, so start with small projects and experiment with different techniques and powders to find what works best for you.

By following these steps and taking appropriate safety precautions, you can successfully powder coat objects at home and achieve professional-quality results.

Application Methods:

Powder coating can be applied using several different methods, each offering unique advantages and suitability for specific applications. The two primary application methods are:

Electrostatic Spray Gun

In this method, the powder coating is electrostatically charged as it exits the spray gun, creating a positively charged cloud of particles. The object being coated is grounded, causing the charged particles to adhere evenly to its surface. Electrostatic spray guns are widely used for their efficiency, uniform coverage, and ease of use.

Fluidized Bed Dipping

This method involves preheating the substrate and then dipping it into a fluidized bed of powder-coating particles. The heat causes the powder particles to melt and flow, forming a smooth and uniform coating on the object’s surface. Fluidized bed dipping is commonly used for coating small, heat-resistant parts with complex shapes.

How To Build A Powder Coating Oven

Building a DIY powder coating oven requires careful planning, knowledge of basic electrical and construction principles, and adherence to safety protocols. Here’s a general guide to building a powder-coating oven.

Design and Planning

Measure the size and capacity of the oven based on the size of the objects you plan to coat. Decide the heating source, if it’s gas or electric, based on your budget and available resources. Sketch out a design for the oven which includes dimensions, materials, and layout.

Gather Materials and Tools

Purchase materials which include sheet metal, insulation, heating elements, temperature controller, and thermostat. Gather tools including a drill, rivet gun, screwdriver, wrenches, and safety equipment like gloves and goggles.

Construct the Frame

Build a solid frame using metal studs or angle iron and make sure it’s large enough to facilitate the required oven size. Attach the frame securely to a stable base or platform.

Install Insulator

Line the inside of the frame with high-temperature insulation material such as ceramic fiber blankets or mineral wool. Use high-temperature adhesive or metallic connectors to secure the insulation in place.

Install Heating Elements

Identify the placement of heating elements based on the oven’s design. Install electric heating elements evenly spaced through the oven and make sure they’re secured and wired according to manufacturer specifications. For a gas oven, install a gas burner system according to manufacturer instructions.

Fix internal lining

Line the interior of the oven with a heat-resistant material such as stainless steel or galvanized sheet metal. Secure the liner in place using screws or rivets, ensuring all seams are sealed to prevent heat loss.

Install Temperature Control System

Install a digital temperature controller and thermostat to regulate the oven temperature. Connect the temperature controller to the heating elements according to manufacturer instructions. Test the temperature control system to ensure accurate temperature monitoring and adjustment.

Finish and integration

Double-check all connections and fastenings to ensure they’re secure. Test the oven to ensure it reaches the desired temperature and maintains consistent heat. Make any necessary adjustments or modifications to improve performance.

Safety Precautions

Install proper ventilation to remove fumes and prevent the buildup of combustible gases. Place a fire extinguisher nearby in case of emergencies. Always wear appropriate safety gear, including gloves and goggles, when operating the oven.

Assessment and adjustment

Test the oven with a few small powder coating projects to ensure it produces satisfactory results. Calibrate the temperature controller as needed to achieve accurate and consistent temperatures.

Building a DIY powder coating oven requires time, effort, and attention to detail, but with proper planning and construction, you can create a reliable and efficient oven for your powder coating projects. If you’re unsure about any aspect of the construction process, consult with a professional or experienced DIYer for guidance.

Advantage Of Powder Coating

Powder coating offers numerous benefits over traditional liquid paint finishes. The benefits of powder coating include:

Strength

Powder coatings are highly chipping resilient, scratching, fading, and other forms of wear and tear, making them ideal for applications requiring long-lasting protection.

Eco-friendliness

Powder coatings emit insignificant amounts of volatile organic compounds (VOCs) compared to liquid paints, making them more environment-friendly and safer for both users and the environment.

Smooth coating

Powder coatings provide consistent coverage without drips, runs, or drops, resulting in a smooth and consistent finish even on complex shapes and surfaces.it is mostly used by the construction company.

Adaptability

Powder coatings come in a wide range of colors, textures, and finishes, allowing for endless adaptation options to meet specific design requirements and aesthetic choices.

Cost-efficient

While the initial investment in powder coating equipment may be higher than traditional painting equipment, powder coating offers long-term cost savings due to reduced material waste, lower maintenance costs, and increased productivity.

Efficiency

Powder coating is a highly efficient process with minimal overspray and high transfer efficiency, resulting in less material waste and reduced cleanup time compared to liquid painting methods.

Fast Drying Time

Powder coatings typically dry faster than liquid paints, leading to shorter processing times and increased production output.

Chemical durability

Powder coatings exhibit excellent chemical resistance to oils, acids, solvents, and other harsh chemicals, making them suitable for use in demanding industrial and commercial applications.

Ease of Application

Powder coatings can be applied using a variety of methods, including electrostatic spraying, powder dipping, and electrostatic fluidized bed, providing flexibility and diversity in the coating process.

Long-Term Performance

Powder coatings offer long-term performance and color durability, maintaining their appearance and protective properties over time, even in harsh environmental conditions.

Conclusion

In conclusion, powder coating is a highly effective and versatile finishing process that offers many benefits over traditional paint finishes. By understanding the principles and techniques of powder coating, you can achieve professional results and enhance the durability and appearance of your projects. Whether you’re coating automotive parts, furniture, or architectural components, mastering the art of powder coating opens up endless possibilities for creative expression and functional enhancement.

FAQ‘s

Can I do powder coating myself?

Yes, it is possible to do powder coating yourself, especially for smaller projects or items. For this, you require some investment in equipment and materials, as well as knowledge of the process and safety measures.

Can you powder coat without an oven?

Yes, it’s possible to powder coat without an oven by using a heat gun or torch to fix the powder coating. However, this method may not be as effective or durable as oven curing.

What is the purpose of powder coating?

The purpose of powder coating is to provide durable and attractive finishes to surfaces, offering protection against corrosion, chipping, and fading. It is widely used across industries for its longevity and aesthetic appeal.